DLM Edge-of-Dock Levelers

DLM Edge-of-Dock Levelers and Equipment has proven the test of time with its strong and durable design. From the use of structural steel in dock levelers to the mechanics of vehicle restraints, all DLM products are built to last. With facilities in Wisconsin and Arkansas, DLM is proud to manufacture all of its products in the USA.

DLM Edge-of-Dock Levelers – Strength & Durability

DLM Edge-of-Dock Levelers mount directly to the dock face and provide a recommended working range of +/-3″ and a maximum operating range of +/-5″ above or below the dock. The units are offered with either mechanical or hydraulic operation.

DLM Edge-of-Dock Levelers

Mechanically-operated edge-of-dock levelers are the largest selling edge-of-dock levelers in the industry. DLM’s dual extension spring lift mechanism offers proven efficiency and durability. Careful engineering and rugged construction ensure extended life. Operation is safe and easy.

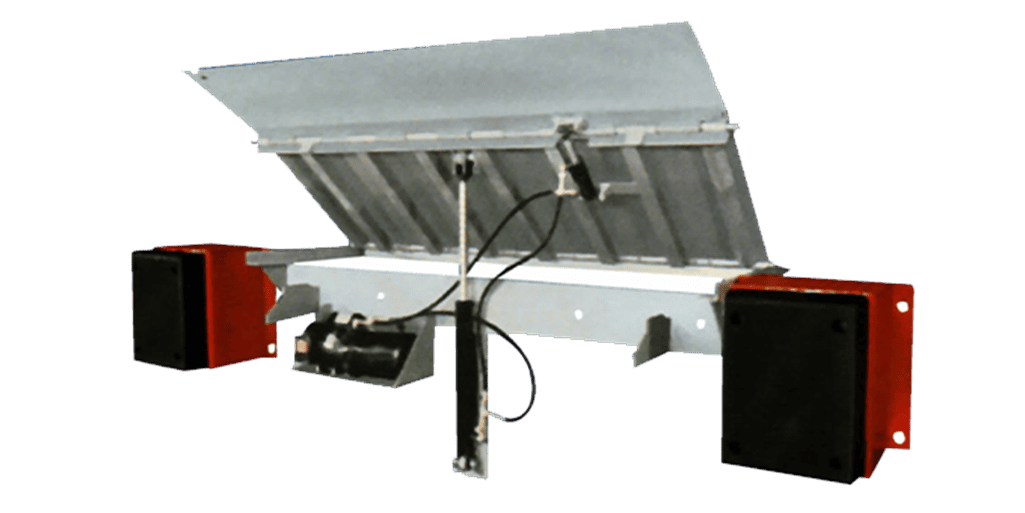

Hydraulically operated edge-of-dock models offer the convenience and safety of push-button control. DLM’s hydraulic design is the finest in the industry, featuring power extension and retraction of the lip and deck. Our exclusive speed control adjusts leveler descent speed.

DLM Edge-of-Dock Levelers – Hydraulic

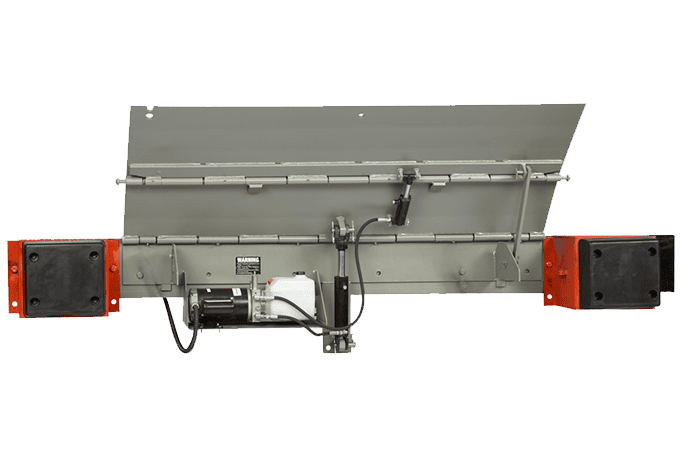

HED Series Hydraulic Edge-of-Dock

The DLM HED Series Edge-of-Dock is a full-featured, fully hydraulic choice for your Edge-of-Dock requirements.

The HED Series Edge-of-Dock is safe, easy to operate, and requires minimal maintenance over the product’s life. A single push button controls both leveler extension and retraction functions and permits the operator an ergonomically advantaged position to operate the leveler.

A choice of single or three Phase voltage is available.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Simple Push-Button Control

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Two Gussets are Standard

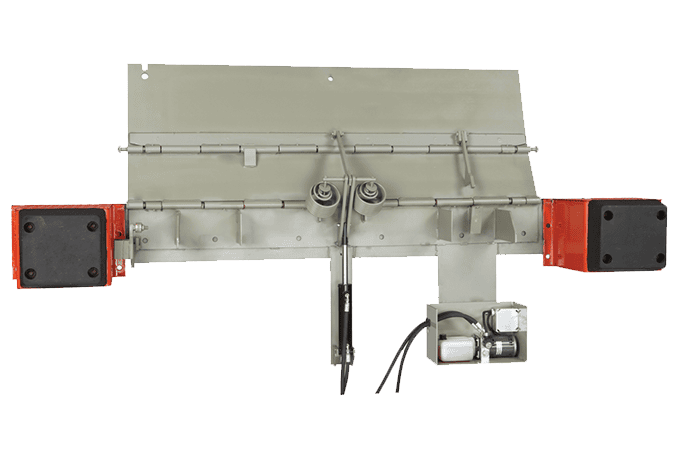

HNL Series Hydraulic Edge-of-Dock

The DLM HNL Series Edge-of-Dock combines the convenience of hydraulics with the simplicity of the Neverlift® exclusive lip extension mechanism to create an affordable push-button alternative.

The DLM HED Series Edge-of-Dock is a full-featured, fully hydraulic choice for your Edge-of-Dock requirements.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Simple Push-Button Control

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Four Gussets are Standard

DLM Edge-of-Dock Levelers – Mechanical

NL Series Mechanical Edge-of-Dock

The DLM “NL” Series Edge-of-Dock is state-of-the-art in lever-operated dock levelers. Simply move the lifting lever 50° away from the dock edge and then return the lever to its original vertical position. The ergonomically friendly activation of the NL Series leveler eliminates the awkward lifting and leaning over the dock motions found on competitive units.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Four Gussets are Standard

DL Series Mechanical Edge-of-Dock

The DLM “DL” series edge-of-dock leveler mounts to the exterior dock face providing a simple and economical alternative to “portable plates” or “pit style” levelers. The DL is ideal for the motor freight industry or those companies with standardized trailer bed heights.

Each DL series model meets or exceeds as industry recommended working range of +/-3″ and a maximum operating range of +/-5″ above or below the dock. To operate the unit, you simply position the DL lifting hook into the lip recess and pull up. By pushing the lifting hook forward as the leveler descends onto the truck bed allows the release and separation of the lifting hook.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Four Gussets are Standard

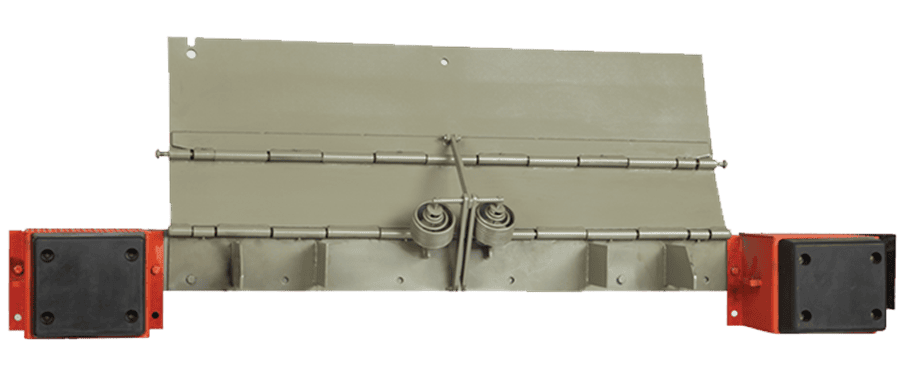

TS Series Mechanical Edge-of-Dock

DLM TS Series Edge-of-Docks are an economical choice costing even less than a comparably-rated portable plate. The advantage of the TS series Edge-of-Dock leveler is the ergonomically friendly positioning of the unit onto the truck bed.

They’re easy and safe to operate, doing away with the heavy lifting generally associated with “hook style” EODs. The TS series features a compact counterbalance making it ideal for recessed leveler installations. They have relatively few moving parts, so maintenance is easy, and durability is outstanding.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Four Gussets are Standard

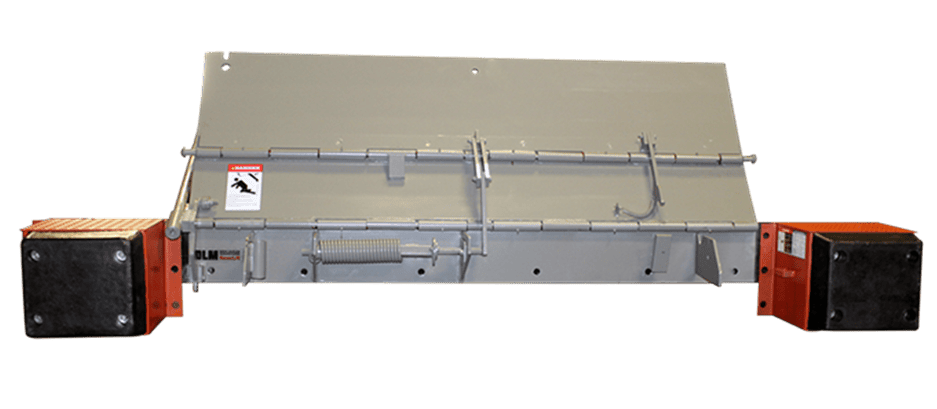

Top-of-Dock Edge-of-Dock

The Top-of-Dock EOD by DLM is economical, allowing you to improve loading dock efficiency at a fraction of the cost of pit-mounted dock levelers. Operation is easy with a simple hydraulic operation.

Features

- Wide Range of Bumper Options

- Heavy-Duty Bumper Blocks are Standard

- Full-Width Distribution Bar

- Milled Lip Edge For Smooth Tire Rollover

- Four Gussets are Standard

Hydraulic Operation (HSM-500)

- NEMA 4 push-button control panel

- Cold-rolled steel hinge pins for added strength and longer life

- Grease fittings throughout

- High-strength steel safety tread plate, 70,000 PSI yield

- Secondary gussets for added strength and extended life

- Heavy duty bumper blocks with 4″x12″x13″ “Tuf-Cord”™ Bumpers

- Fully hydraulic lip & deck cylinders

Call us at (480) 764-3488

Spectrum Facility Solutions, Commercial Doors – 8270 S Kyrene Rd STE 103, Tempe, AZ 85284

Request Facility Services

JOIN OUR TEAM!

We are always accepting applications to find individuals as devoted and driven as our installation team.