Poweramp Hydraulic Dock Levelers

Hydraulic dock levelers are push-button activated. Poweramp Hydraulic Dock Levelers utilize fully powered raise and lip extension functions with hydraulic cylinders, individual or multi-unit hydraulic pumps, and motor stations. Hydraulic levelers are the easiest to operate and have the lowest maintenance available.

Maximize Safety & Efficiency with Poweramp Hydraulic Dock Levelers

Poweramp hydraulic dock levelers are also the safest loading dock choice, as these levelers contain in-line velocity fuses to prevent free fall in a truck pull-out situation. An industry leader in hydraulically operated dock levelers and is known for their levelers’ strength and durability.

Poweramp Hydraulic Dock Levelers

These premium levelers are the industry’s most robust and durable dock levelers, providing a smooth and efficient loading process. Since 1961, Poweramp has been a premier supplier of quality dock levelers and dock equipment, committed to increased efficiency, safety, quality products, and value.

Benefits:

- Safety: Dock levelers reduce fork truck accidents at the dock by smoothly transitioning from the dock floor to the truck floor.

- Productivity: Dock levelers allow for safe and efficient loading and unloading of goods to and from a truck using forklifts or pallet trucks.

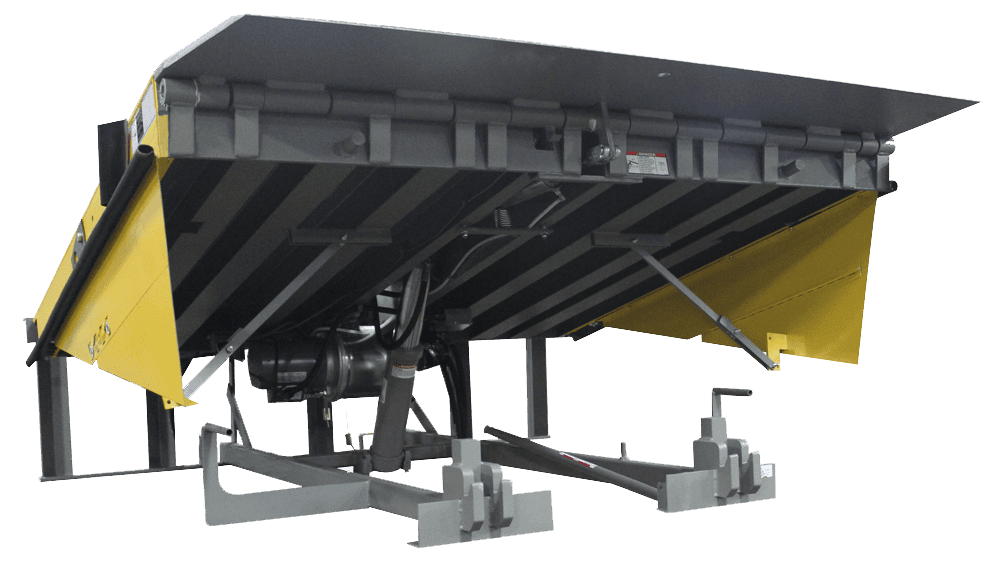

PR Series Hydraulic Leveler

Pit Style Hydraulic Dock Leveler

The PR Series is a heavy-duty, premium quality loading dock leveler that provides unmatched productivity and safety with a superior structural steel design. The PR Series is completely hydraulic in both engineering and operation.

PR levelers feature a patented fluid logic block system that provides unparalleled leveler control and stability. Improved safety, superior design, and low-maintenance costs make the PR Series the finest hydraulic dock leveler in the industry. Max Standard Width – 7′ and Max Standard Length – 12′

Features

- Made in the USA

- Push-button activation

- Hydraulic operation

- 30,000 – 120,000 CIR

- Structural steel w/ channel outboards, four-sided box construction

- Piano-style front and rear hinges

- Hoist cylinder with internal velocity safety stop

- Recessing Lip Cylinder

- Folding toe guards w/ 24″ pit

- Fluid logic block

- Optional Barrier Lip

- Maintenance Inspection Plate

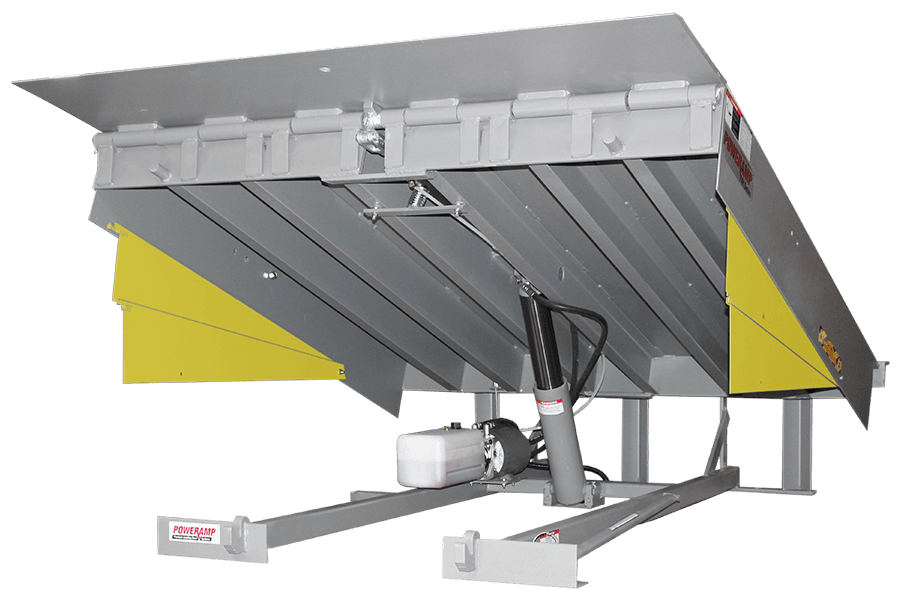

VH Series Hydraulic Leveler

Pit Style Hydraulic Dock Leveler

The VH Series is a fully hydraulic, feature-packed leveler for the value-minded consumer. It combines a structural steel ramp design with a proven hydraulic operation to produce a safe, reliable, economical hydraulic dock leveler.

Hydraulic levelers use integrated features to improve safety and save valuable operation and maintenance time. Max Standard Width – 7′ and Max Standard Length – 12′

Features

- Made in the USA

- Push-button activation

- Hydraulic operation

- 30,000 – 80,000 CIR

- Structural steel w/ plate outboards, four-sided box construction

- Piano-style front and rear hinges

- Hoist cylinder with internal velocity safety stop

- Recessing Lip Cylinder

- Sliding toe guards

- Fluid logic block

- Optional Barrier Lip

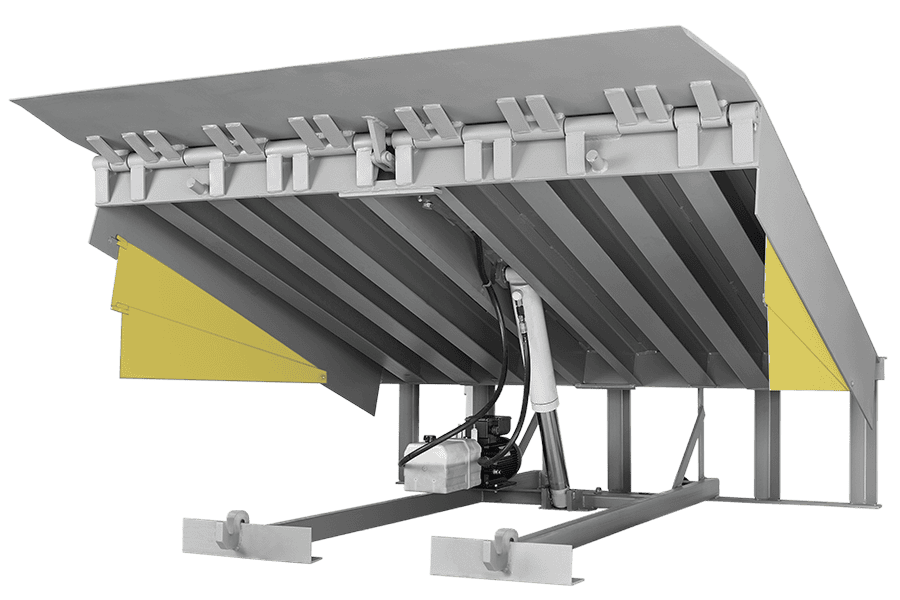

EH Series Hydraulic Leveler

Pit Style Hydraulic Dock Leveler

The EH Leveler combines superior structural steel characteristics with an economically efficient hydraulic system. Beyond obvious structural advantages, EH Series levelers offer various standard features found only on competitive ‘high-end’ models. Max Standard Width – 7′ and Max Standard Length – 10′

Features

- Push-button activation

- Hydraulic operation

- 25,000 – 60,000 CIR

- Structural steel w/ plate outboards, four-sided box construction

- Piano-style front and rear hinges

- Inverted hoist cylinder with external velocity safety stop

- Standard Lip Cylinder

- Sliding toe guards

- Sequence valve

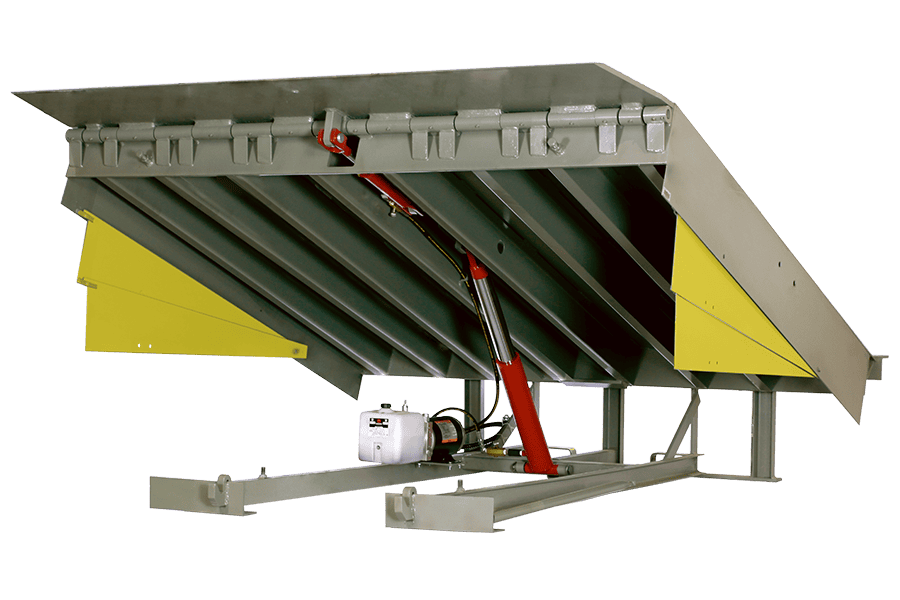

LHP Series Hydraulic Leveler

Pit Style Hydraulic Dock Leveler

The LHP Series dock leveler combines cost-effective hydraulic technology with our efficient deck and frame design to produce a reliable, price-sensitive hydraulic dock leveler.

The structure of the LHP incorporates a box construction deck with an efficient deck and frame design. LHP levelers have added safety features and save valuable time in operation and maintenance. Max Standard Width – 7′ and Max Standard Length – 8′

Features

- Push-button activation

- Hydraulic operation

- 25,000 – 40,000 CIR

- Four-Sided box construction

- Piano-style front and rear hinges

- Hoist cylinder with external velocity safety stop

- Standard Lip Cylinder

- Sliding toe guards

- Sequence valve

Call us at (480) 764-3488

Spectrum Facility Solutions, Commercial Doors – 8270 S Kyrene Rd STE 103, Tempe, AZ 85284

Request Facility Services

JOIN OUR TEAM!

We are always accepting applications to find individuals as devoted and driven as our installation team.

In-line Velocit Fuse

In-line Velocit Fuse Fluid Logic Block

Fluid Logic Block Maintenance Check Plate in Deck

Maintenance Check Plate in Deck Deck Mounted Pump and Motor

Deck Mounted Pump and Motor Recessing Lip Cylinder

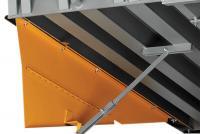

Recessing Lip Cylinder Folding and Locking Toe Guards

Folding and Locking Toe Guards Connect Online

Connect Online Optional Inter-Lockable Electrical Push Button Controls

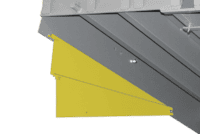

Optional Inter-Lockable Electrical Push Button Controls Sliding Style Toe Guards

Sliding Style Toe Guards All Structural Steel Design

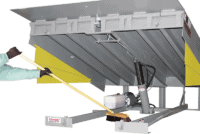

All Structural Steel Design Simple Push-Button Design with Lip Control

Simple Push-Button Design with Lip Control Translucent Hydraulic Reservoir

Translucent Hydraulic Reservoir Platform Free-All Protection

Platform Free-All Protection Inverted Hoist Cylinder

Inverted Hoist Cylinder Four-Sided Box Construction

Four-Sided Box Construction Fully Hydraulic Yieldable Lip Cylinder

Fully Hydraulic Yieldable Lip Cylinder