Poweramp Vehicle Restraints

Many forklift accidents occur every year caused by a truck prematurely departing from the dock or creeping away due to loading and unloading momentum. Installing Poweramp Vehicle Restraints can help prevent these accidents by securing a trailer to the dock and providing better communication between the truck driver and dock attendant.

Improve Safety At The Loading Dock With Poweramp Vehicle Restraints

Poweramp Vehicle Restraints

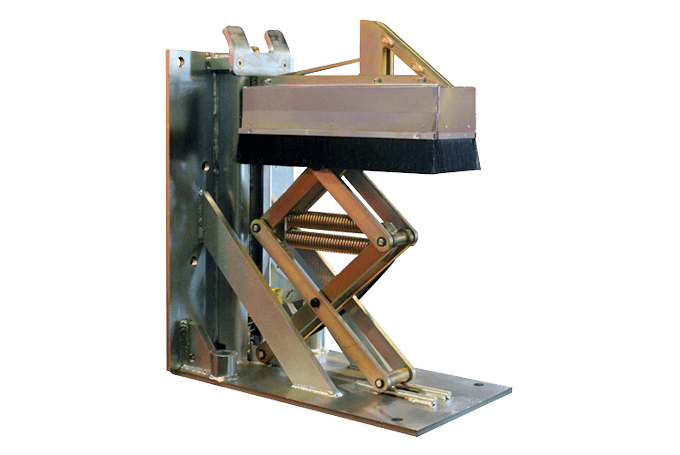

PowerHook® Series Automatic Restraint

Loading Dock Truck Restraint

The PowerHook is a non-impact, self-aligning hydraulic restraint stored in the dock pit and is the most effective truck restraining device available on the market.

The PowerHook® restraint is anchored in the loading dock pit for maximum holding strength. The hook remains recessed and protected behind the pit wall until activation, making it easy to maintain the dock exterior. Because it stores in the pit, the restraint is completely concealed and out of the way. This is a great advantage when clearing the drive approach of snow or debris.

Features

- Stored in the dock pit and out of the way when clearing the drive approach of snow or debris.

- Actively seeks and secures a trailer’s Rear Impact Guard (RIG).

- Maintains a positive hydraulic hold of the RIG for zero running room.

- Rapidly flashing exterior light if the truck attempts to pull away while secured.

- LED 3-light system for advanced communication between the truck driver and dock attendant.

Designed to withstand a pulling force over 35,000 lbs, providing an extra margin of safety and protection. This restraint has the widest service range in the industry, with a horizontal range of 0” to 15” from the building and a vertical range from 7” to 34” off the drive. Extended ranges are available for special applications. With over 10,000 applications over a twenty-year period, the durability and reliability of PowerHook® are unmatched in the industry.

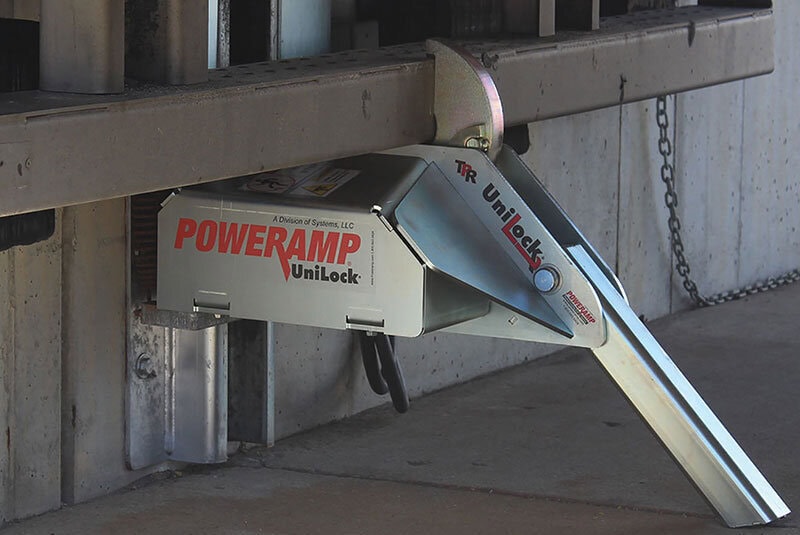

TPR UniLock® Automatic Restraint

Loading Dock Truck Restraint

An upgrade to the standard TPR Series, the UniLock has an added internal safety mechanism and an advanced cam design that rotates the hook away from the trailer’s Rear Impact Guard (RIG) to release. “RIG Wedge” pressure. The UniLock has an advanced cam design that first rotates the hook away from the RIG to remove the pressure and then rotates down to a stored position.

The UniLock vehicle restraint also has an internal safety mechanism that locks the restraint’s hook in place when pressure is applied, maintaining a secure engagement. That makes it universally effective on any obstructed Rear Impact Guard (RIG), including intermodal trailers with cover plates that prevent the restraint’s hook from latching on top of the RIG.

Features

- Automatically releases RIG Wedge pressure without the trailer reversing.

- Locking mechanism to prevent the restraint from disengaging the trailer’s RIG when pressure is applied.

- Universally effective on any obstructed Rear Impact Guard, including intermodal trailers with cover plates.

- LED 3-light system for advanced communication between the truck driver and dock attendant.

Designed to withstand a pulling force over 32,000 lbs and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above the drive approach. The integral motor, gear, and brake assembly are designed explicitly for the UniLock, and the UniLock vehicle restraint is highly adaptable to new or existing loading docks.

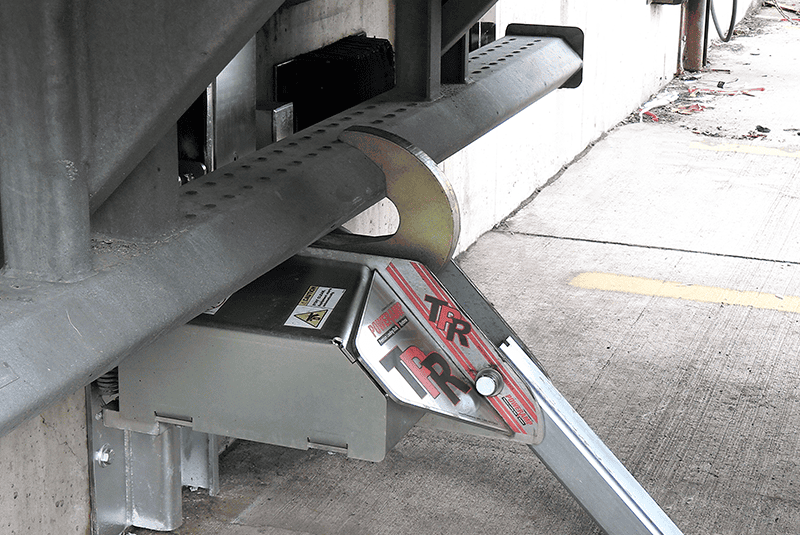

TPR® Series Automatic Restraint

Loading Dock Truck Restraint

The TPR is a trailer-positioned vehicle restraint mounted to the face of the dock and utilizes a motor and gears to rotate a hook and secure the trailer. The Poweramp TPR® truck positioned vehicle restraint is designed to automatically position itself and secure a trailer’s rear impact guard (RIG) to reduce the likelihood of premature trailer separation during the loading/ unloading process.

Features

- The unit automatically positions itself when impacted by the RIG.

- Motor and gears keep hooking continuously engaged with the RIG.

- LED 3-light system for advanced communication between the truck driver and dock attendant.

Designed to withstand a pulling force over 32,000 lbs and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above the drive approach. The integral motor, gear, and brake assembly is specifically designed for the TPR®. The TPR® vehicle restraint is highly adaptable to new or existing loading docks.

PowerStop® Series Automatic Restraint

Automatic Loading Dock Truck Restraint

The PowerStop Automatic is a non-impact, hydraulic vehicle restraint that is exterior mounted to the front of the loading dock.

The PowerStop® fully automatic vehicle restraint (AAL) is an easy-to-install, affordable restraining system. It comes equipped with a RIG sensor bar that notifies dock workers if the restraint’s arm is not securely engaged with the trailer’s Rear Impact Guard.

Features

- Low profile, non-impact design

- The hydraulic operation vertically raises the restraint and engages the RIG.

- LED 3-light system for advanced communication between the truck driver and dock attendant.

The PowerStop will withstand up to 32,000 lbs. of pull-out force and has a horizontal service range of 0” to 10” and a 12” minimum to 29.5” vertical service range. It can be integrated with any mechanical, hydraulic, or pneumatic dock leveler, making it extremely versatile for various applications. The PowerStop® is available as a stand-alone unit or can be integrated with other loading dock equipment.

PowerStop® Series Manual Restraint

Manual Loading Dock Truck Restraint

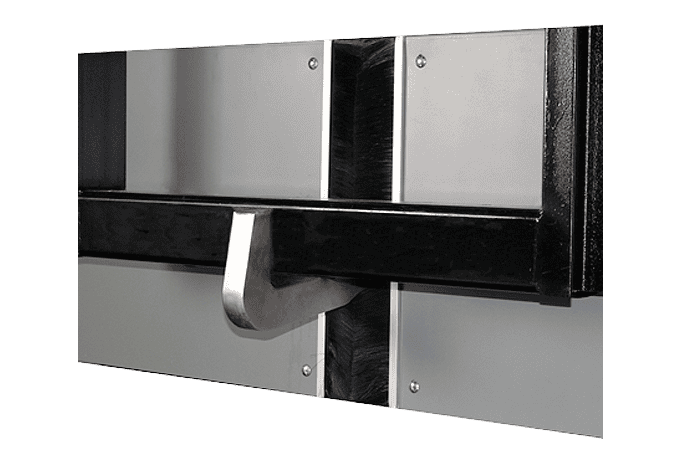

The PowerStop Manual is a non-impact, manually operated vehicle restraint exterior mounted to the front of the loading dock.

The PowerStop® is a non-impact, self-aligning, mechanically operated truck restraining system. An optional light communication package can be added to the MML and MAL, which can also be upgraded to iDock Controls with an interactive message display. The MAL comes equipped with a RIG sensor bar that notifies dock workers if the restraint’s arm is not securely engaged with the trailer’s Rear Impact Guard.

Features

- Economical solution for a vehicle restraint.

- Low profile, non-impact design

- LED light communication is available with the MML and MAL.

The PowerStop® will withstand up to 32,000 lbs. of pull-out force and has a horizontal service range of 0” to 10” from the face of the dock bumpers and a vertical range of 12” to 29.5”. The PowerStop® is a versatile restraint that can be integrated with mechanical, hydraulic, or pneumatic dock levelers and edge-of-dock or top-of-dock units.

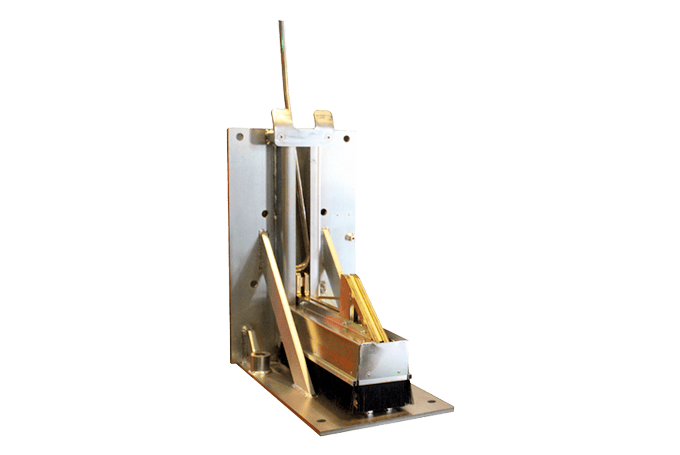

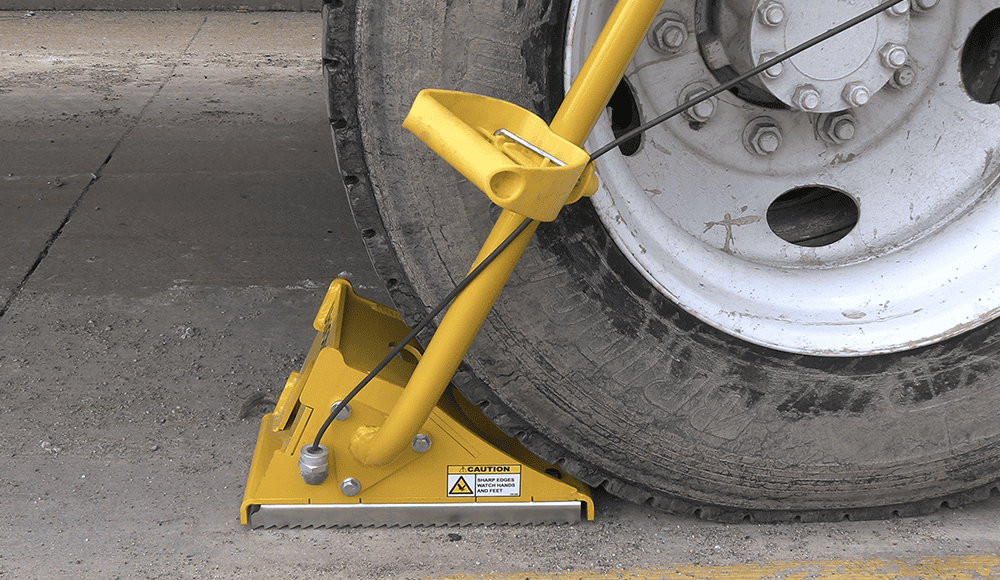

UniChock™ Vehicle Restraint

Wheel-Based Vehicle Restraint

The UniChock is a wheel-based trailer restraint with advanced light communication and is available as a standalone unit or integrated with other dock equipment. Universally effective in most conditions, the unit helps prevent unexpected trailer departure or movement from the loading dock during the loading process.

Once a trailer is fully backed and parked against the dock bumpers, the UniChock is removed from the storage bracket and placed under the front of one of the trailer’s back tires. This will sound an audible indicator and display a message on the iDock Controller that the unit is in a safe position. The dock attendant can then open the door and deploy the leveler.

Features

- Universally Effective

- Audible Alarms

- Lightweight, Durable Design

- Advanced Communication

- Replaceable Traction Teeth

The UniChock is equipped with advanced safety features. In addition to the controller message display and light communication, If the chock is moved to an unsafe position during loading, an audible alarm will sound until the restraint is back in the correct position.

After loading is complete, the dock attendant stores the leveler and closes the overhead door, which will then sound and display indications to return the UniChock to the storage bracket.

Call us at (480) 764-3488

Spectrum Facility Solutions, Commercial Doors – 8270 S Kyrene Rd STE 103, Tempe, AZ 85284

Request Facility Services

JOIN OUR TEAM!

We are always accepting applications to find individuals as devoted and driven as our installation team.